MARATHON HEATER (INDIA) P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MARATHON HEATER (INDIA) P.LTD.

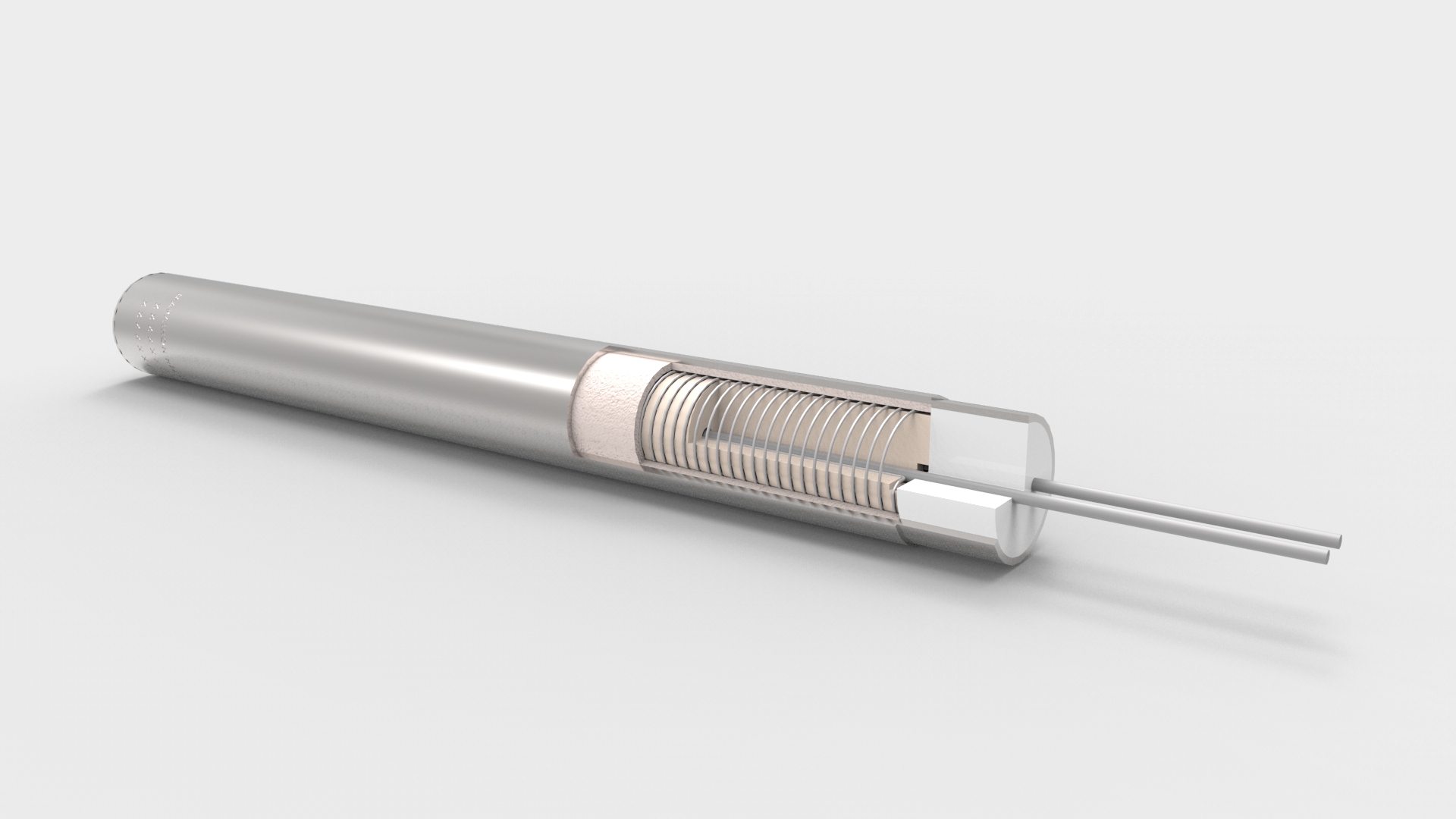

Bobbin And Pipe Heater

Bobbin heaters are mainly used for direct heating of air and indirect heating of liquids and gases where the element is fitted into a pocket in the process tank or system so that the element may be replaced without draining down the system or vessel. Highly energy efficient as 100% of the heat is generated within the solution. Extensively used for transmission of heat, these heaters are available in various specifications that meet the individual necessity in the best possible manner. Bobbin heaters are made with sheathed and without sheathed material. The sheath material ranges from nickel plated mild steel, copper, nickel plated copper to stainless steel. Resistance wire are supported on refractory insulators and connected to a terminal block at one end. Construction is done with Ceramic link bobbins in either single or 3 phase connections. Thermowell can be provided for accurate temperature sensing or other controls can be provided as well. The element allows easy installation and handling. They are normally manufactured for horizontal mounting, but may be specially designed and constructed for vertical installation. Designed for any voltage or wattage within manufacturing limits, bobbin heaters are mainly used for low watt density heating and low temperature range. Known to be one o

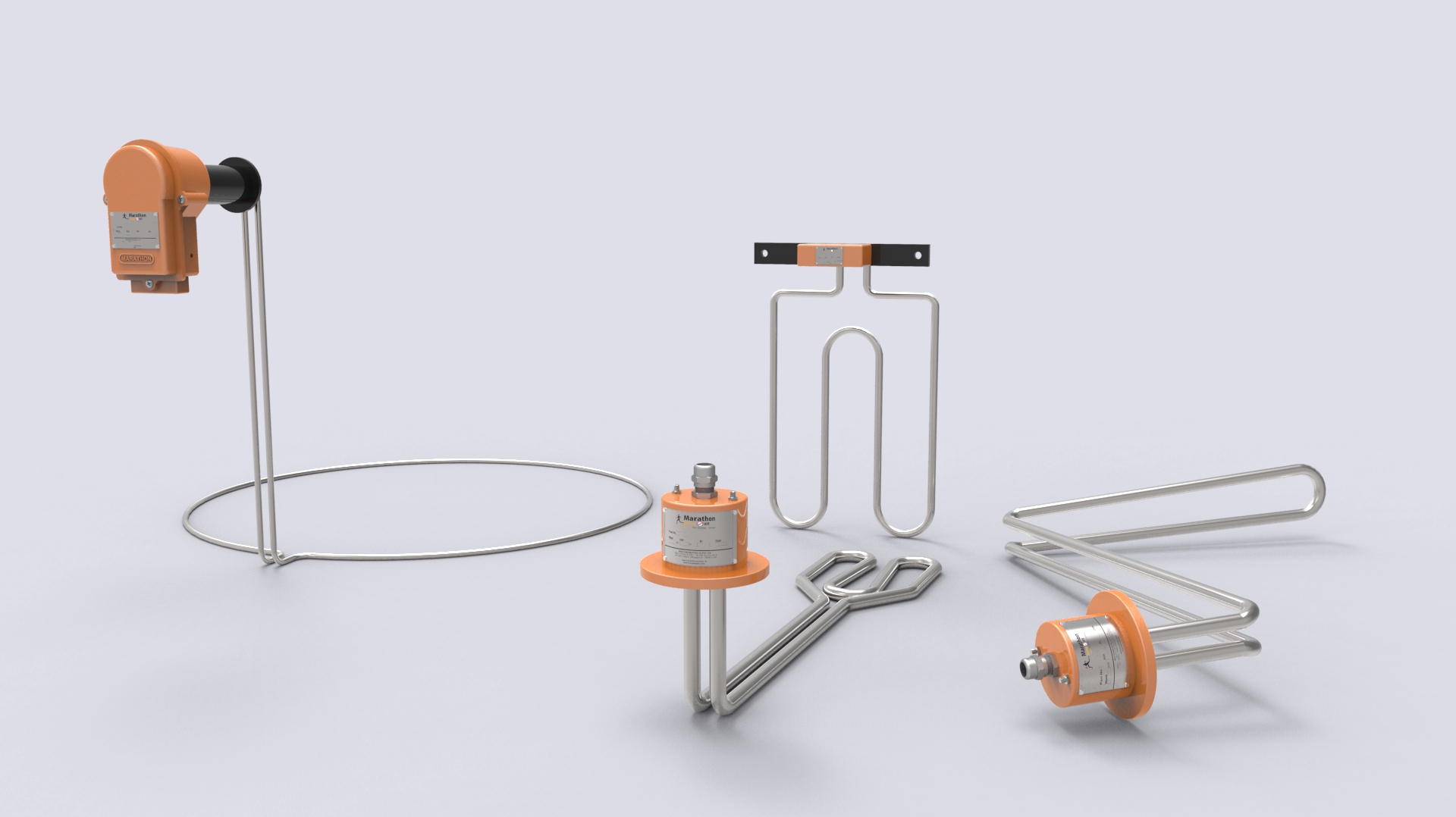

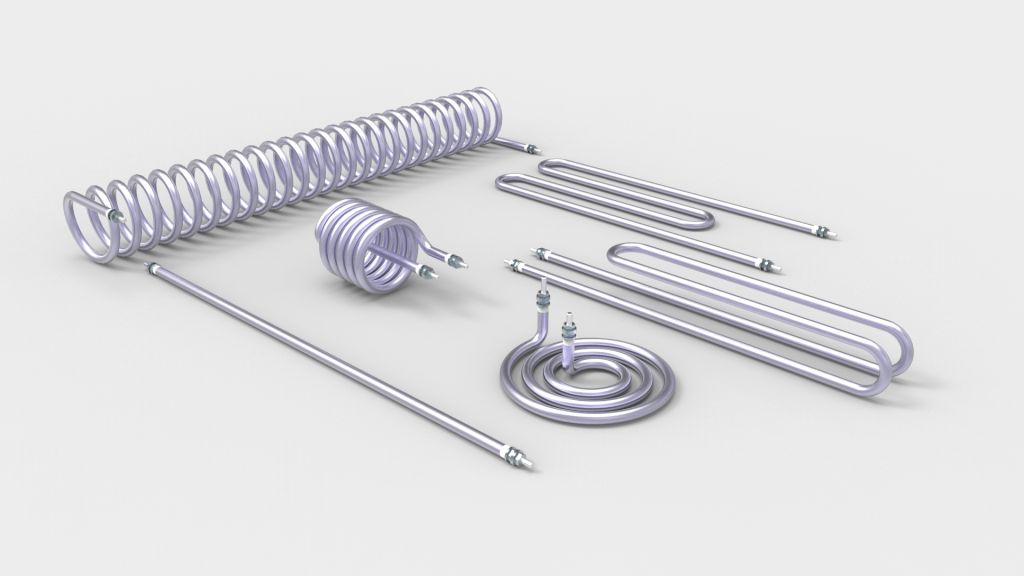

Over The Side Immersion Heater

When the customer demands are such that through-the-wall heaters cannot be installed, portability is required, heaters are to be removed without emptying the tanks, or when there is no access to the liquid medium except from the top, then over the side heaters is the right option. Various shapes and sizes are provided to fit customer dimensions such as, “ installed-from- the- top” ( L or O shaped) which can easily slide into tanks, vertical loop which are suited for open tank applications or drum heaters for direct immersion in drums. Brackets, risers, legs or junction boxes are used to support the heater if desired. Over the side immersion heaters can be installed in the upper portion of tanks, with the heated portion directly immersed along the side or at the bottom, hence the name. This not only provides ample operating space in the tank, but also allows easy removal and portability. Together with thermowells and control system, this industrial heater, renders practicality and economic feasibility. Mobility is the unique feature of this heater, hence can be used in more than one container, making it a preferred choice for projects. Over the side immersion heaters are the most peculiar heater and stands out among st the immersion heaters.

Tubular Heater

Known for its versatility, ruggedness and dependability, tubular heaters can virtually be factory-configured to suit a variety of industrial heating applications. Tubular elements are frequently regarded as the foundation of all heating elements. The basic design consists of a resistance wire/coil precisely centered in a metal sheath. This wire/coil is surrounded by magnesium oxide to provide efficient heat transfer from coil to heating medium. Diameters are varied to give customized design and adjustable watt densities for best performance and long life. Bending radius is carefully chosen so as to give optimum performance. Tubular heating elements perform heat transfer by all three modes (conduction, convection and radiation). They are available in both single ended and double ended designs.

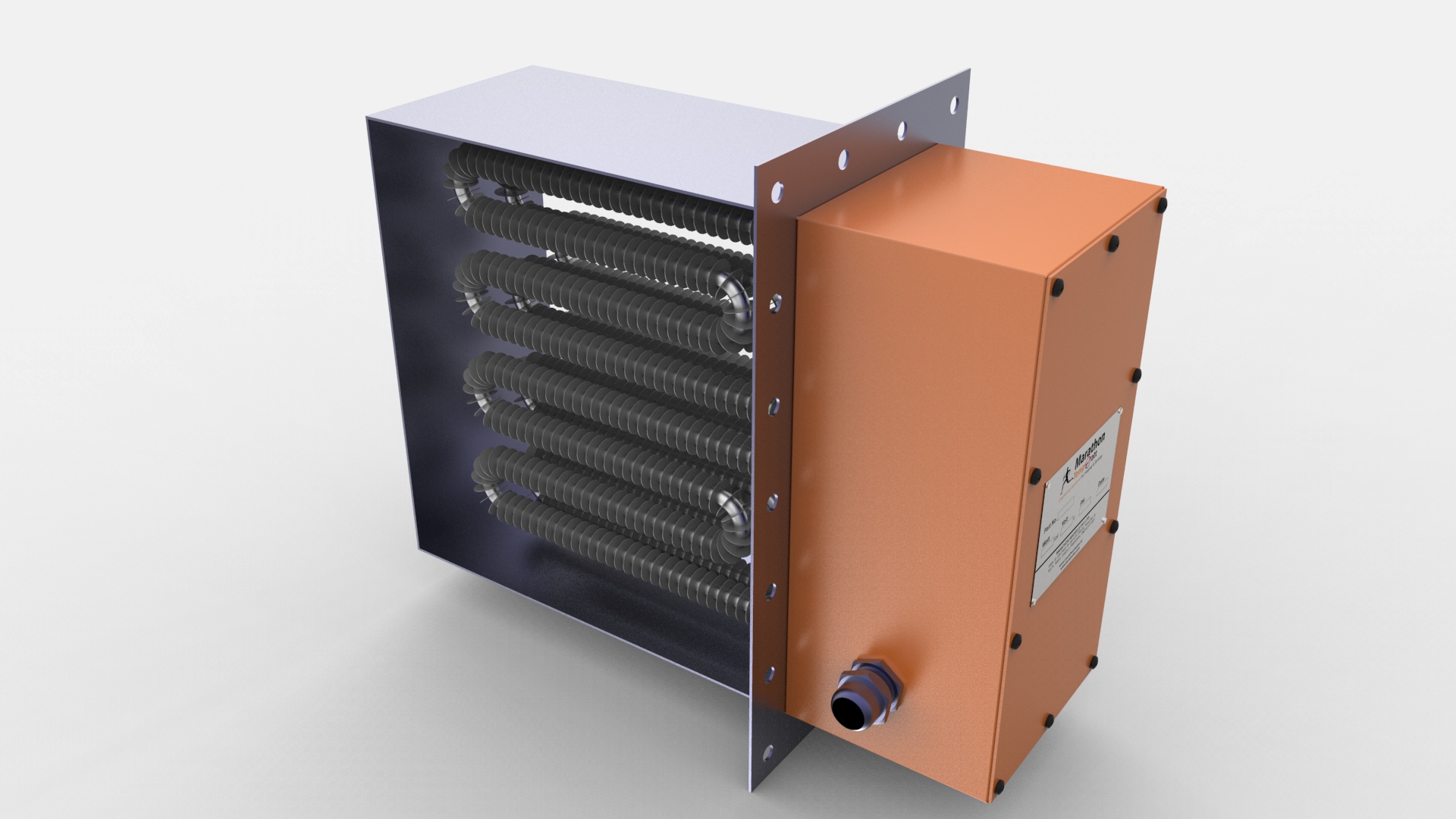

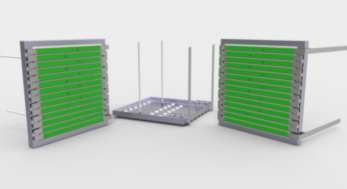

Finned Tubular Heater

Finned tubular heaters are superior to tubular heaters since fins greatly increase surface area, permit faster heat transfer to air and permits putting more power in tighter spaces—like forced air ducts, dryers, ovens and load bank resistors resulting in lower element surface temperature. They are made of up of tubular heating elements and are equipped with electro galvanized steel fins. Mechanically bonded continuous fins assure excellent heat transfer and helps prevent fin vibration at high air velocities. As the surface area is increased and heat transfer is improved due to fins, it results in lower sheath temperature and maximizing of element life.

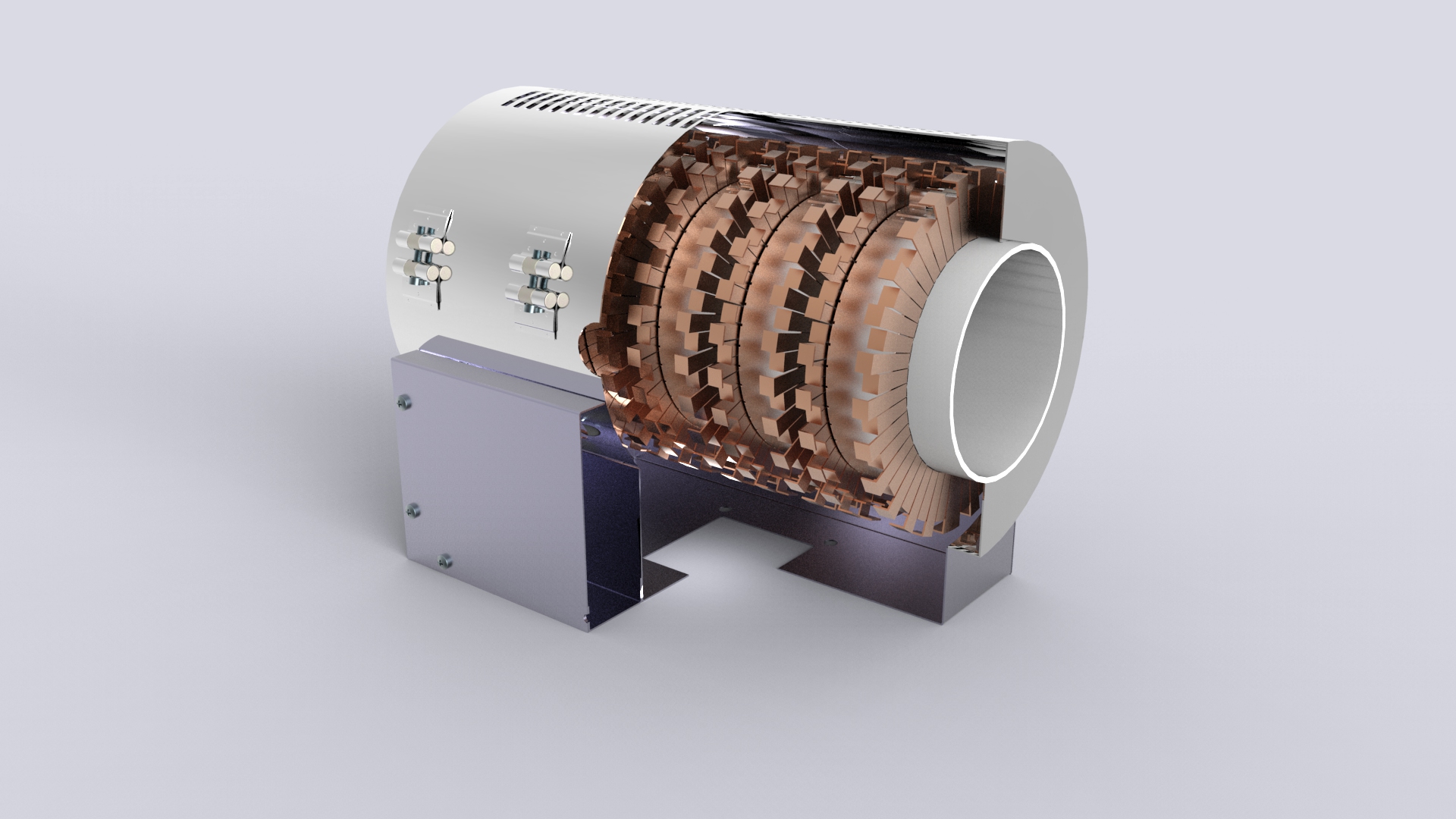

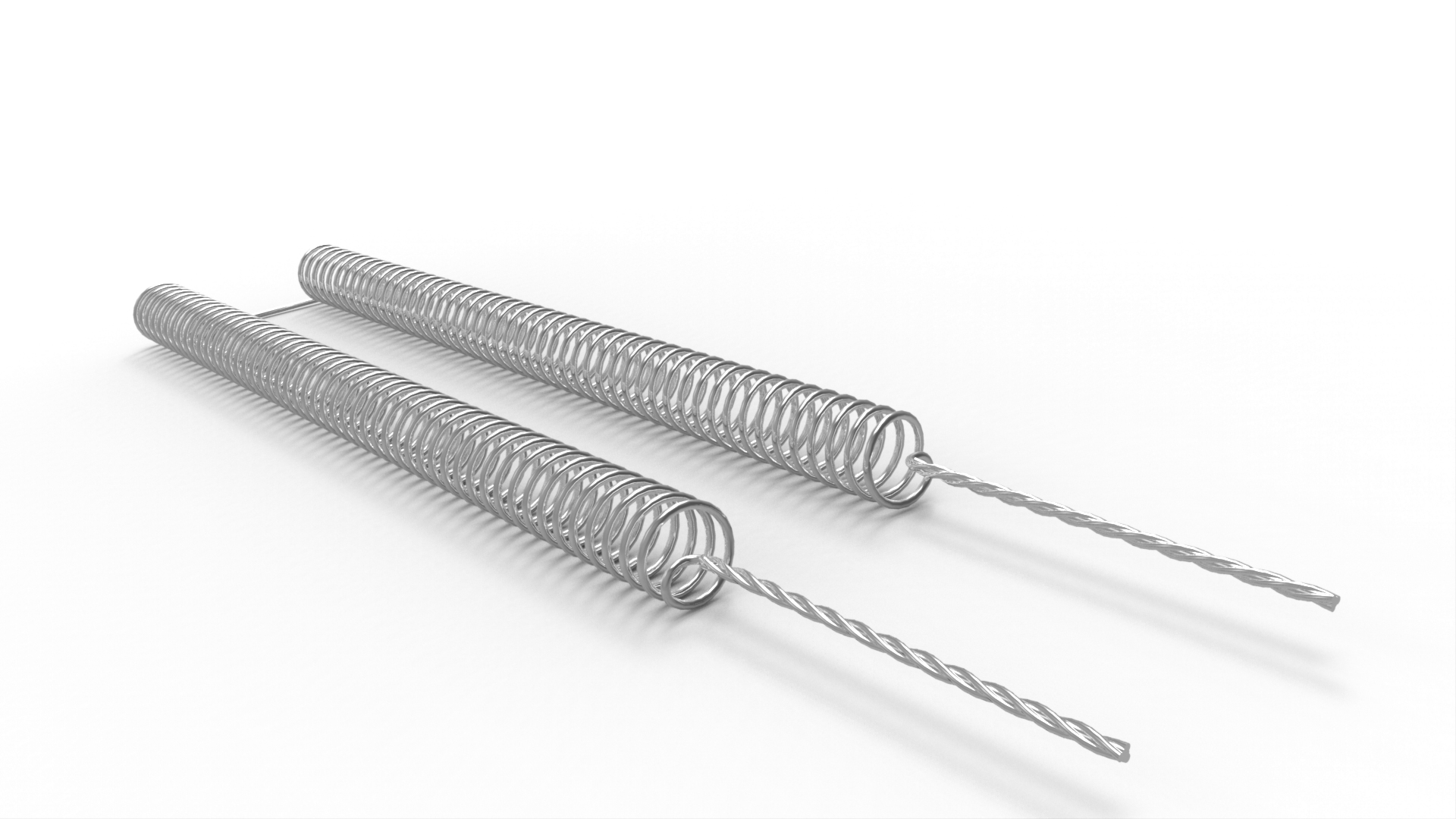

Open Coil Heater

Open coil heating elements have open circuits consisting of coiled resistance wire (usually Ni- Chrome or FeCrAl) fixed onto a supporting element that heat the medium directly. Termed as the most efficient and versatile while also the most economically feasible solution for heating, these elements have fast heat up times that improve efficiency and have been designed for low maintenance and inexpensive replacement parts. When an electrical current is applied to the wire, it gives off heat. The wire is connected to the control panel which regulates the amount of heat provided by the electric heater and fills the tunnel of the air handling unit. Because of the low mass and fast response time, SSR or SCR switching devices are advisable. They serve as an indirect solution to decrease watt density requirements and prevent heat sensitive materials from breaking down. The heater can be formed into a compact, coiled nozzle heater supplying a full 360 degrees of heat with optional distributed wattage.

Infrared Radiant Heater

Infrared radiant heaters are electric heaters specifically designed to emit infrared heat, where heating by other means is not ideal. As they rely on infrared energy, they are able to transmit heat without losing it to the outside. Infrared heaters use either quartz element or tubular element that radiate ample heat because it attains high temperatures. Terminals are protected by waterproof housing and are used in conjunction with control panels. If the tubular elements need to be replaced, they are available at an economic cost. Different lengths and sizes are available to meet specifications. Radiant heaters are high intensity heaters and used where high temperatures are necessary. These heaters are simple, economic, easy to clean, cost effective and efficient.

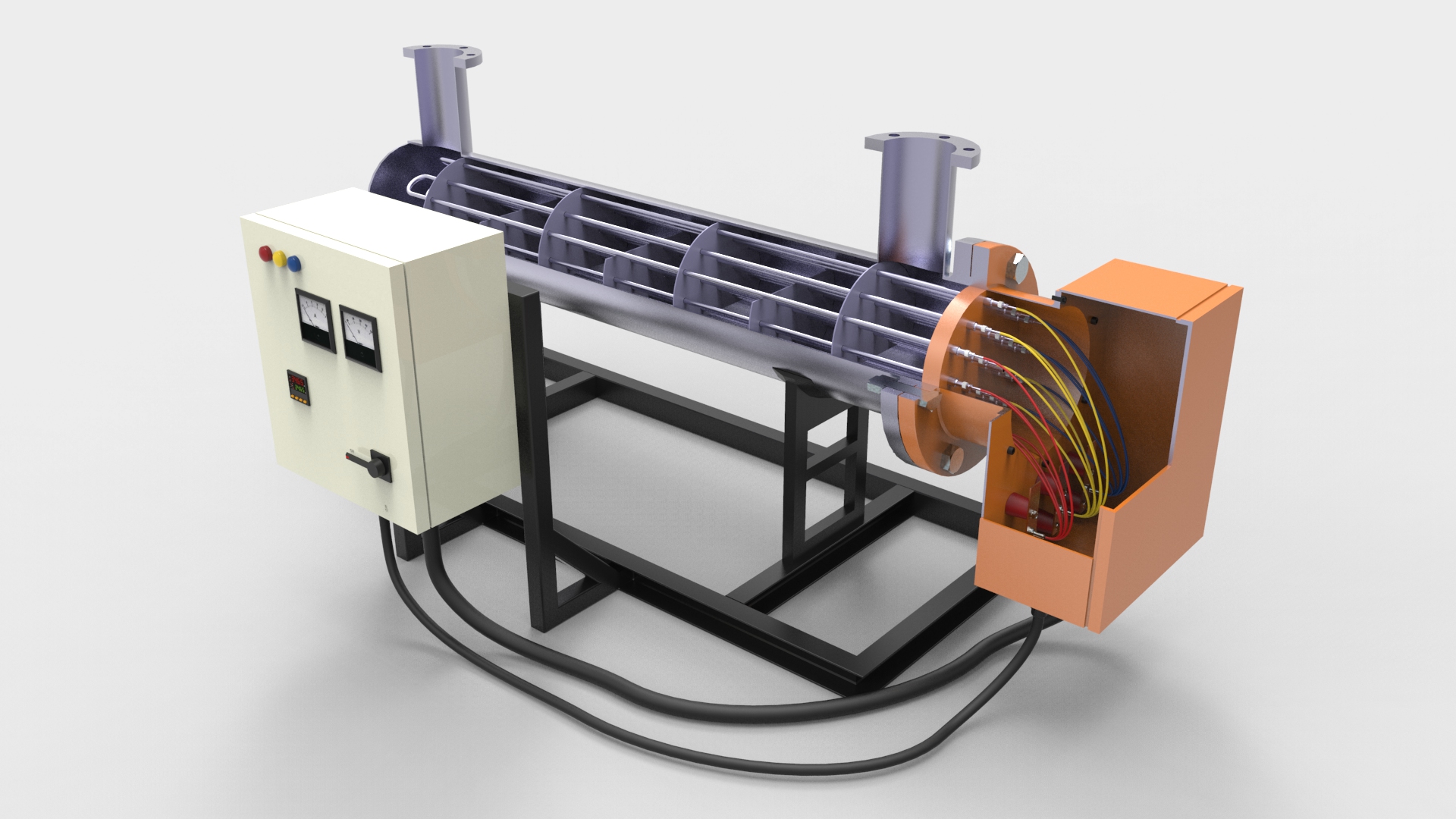

Circulation Heater

Circulation heater (a.k.a inline heaters) is basically an immersion heater covered by an anti-corrosion metallic vessel chamber. It is accompanied by National Pipe Thread (NPT) screw plug or ANSI flange heater assemblies mated with a pressure vessel. The vessel is mainly used to provide insulation to prevent heat loss in the circulation system. An inlet flange transports the fluid into the circulation system, which is then circulated and heated until the desired temperature is reached. The heating medium will then flow out of the output flange at a fixed flow rate decided by the temperature control mechanism. Since it is a compact heating system, the operation is fast and executed in a short time. The heat generated is evenly distributed and the efficiency of the heater is high. Drain valves are also provided to remove leftover fluids or residues. Temperature sensors can be used with any control to achieve the desired temperature range. To manage the liquid flow rate of the heater, the wattage can be manipulated. When the requirement is such that liquid is to be pumped around anyway, a circulation heater is a logical choice.

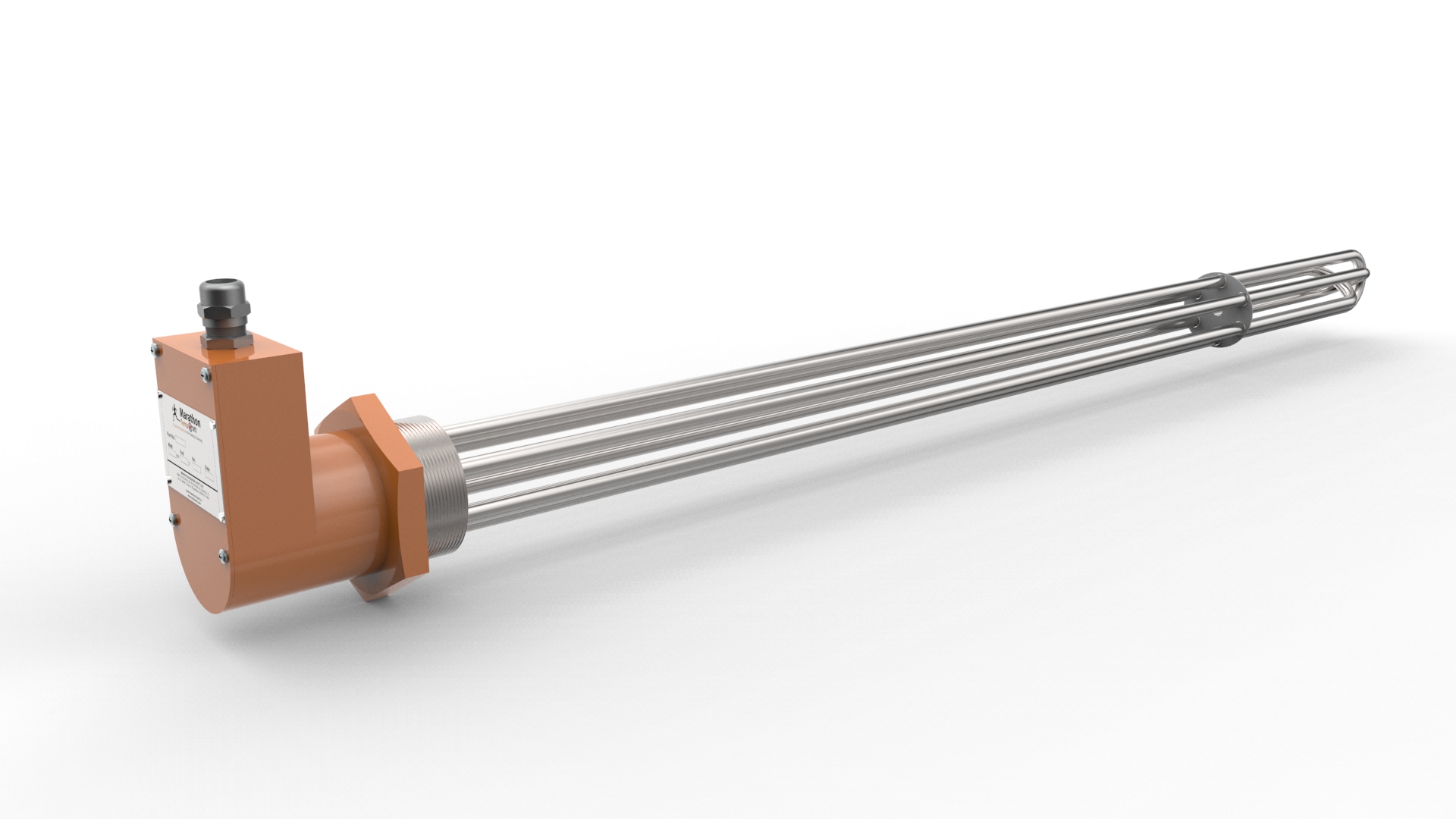

Screw Plug Heater

Screw Plug Immersion Heaters consist of hairpin tubular elements welded or brazed into a screw plug and provided with terminal enclosures for electrical connections. They can be screwed through a threaded opening into a tank wall or vessel. Welding or brazing depends upon the element sheath and plug material compatibility. Depending upon the customer requirement, thermo wells, thermostats or control panels can be used with these heaters to meet the objective of precise temperature control.

Bundle Rod Heater

As the name suggests, bundle rod heater consists of circular ceramic beads that hold the heating elements. Also known as Tubothal Heating elements or Bayonets, they are designed for long life and maintenance free operation. The elements can be provided in almost any length but the standard dimensions available are 68 to 170 mm (2.6 to 6.6 inch). These heaters can be used as standalone elements or inside radiant tubes. Because of the ingenious design, Bundle rod heating elements deliver a much higher power

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.